Air separation - the process of isolating atmospheric gases such as oxygen, nitrogen, and argon - relies on technologies like cryogenic distillation, membrane separation, pressure swing adsorption (PSA), and chemical absorption. Ambient air, composed of roughly 78% nitrogen, 21% oxygen, and 1% argon, CO₂, and trace gases, is first compressed, then cooled in a “cold box” where individual components liquefy at different temperatures and are drawn off under controlled conditions. Once separated, these gases are recompressed for storage, transportation, or further on-site use.

The purity and reliability of filtered air are critical: hydrocarbon vapors and lubricant carry-over in feed air can foul molecular sieves, causing blockages and performance loss. Conventional filters - coalescing oil separators combined with activated-carbon beds - gradually saturate, risking breakthrough contamination that jeopardizes both process uptime and product quality.

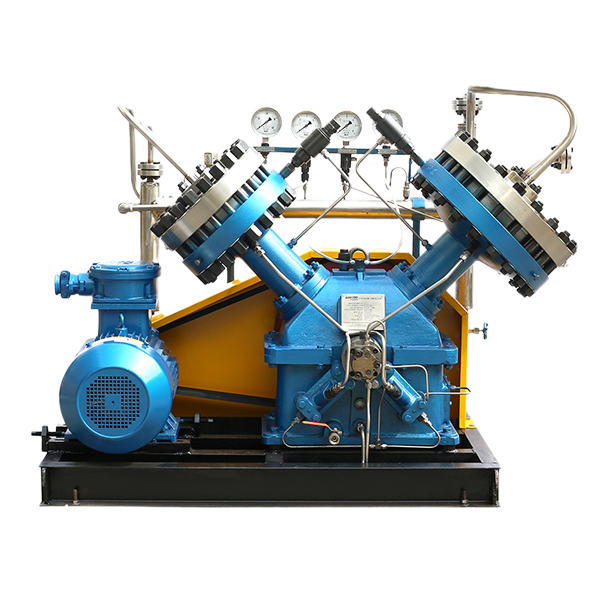

As the cornerstone of any air separation unit (ASU), the compressor’s performance dictates overall plant efficiency and stability. ADEKOM brings over 20 years of dedicated experience in designing oil-free and oil-lubricated compressor packages, as well as turnkey purification systems, to ensure an uninterrupted supply of ISO 8573-1 Class 0 oil-free air. Our solutions have been deployed in hundreds of ASU projects worldwide, delivering high-purity gas for applications across metallurgy, petrochemicals, chemicals, machinery, electronics, and aerospace.

Beyond compressors, ADEKOM provides complete ASU support equipment - including booster compressors for high-pressure oxygen or nitrogen circuits, nitrogen recirculation compressors, and, where required, argon compression units. We engineer twin-process packages (e.g., primary N₂ feed plus N₂ recycle) and supply all ancillary systems such as inlet filtration, aftercoolers, and instrumentation. With our extensive compressor portfolio and deep air-separation expertise, ADEKOM delivers turnkey, high-purity gas solutions that optimize performance, reliability, and lifecycle value in every air-separation application.

Separação do Ar / Separación del Aire / فصل الهواء(أو: عملية فصل مكونات الهواء)