Compressed air inline filters are now

recognized as being an integral part of any system. Few, if any, compressed air

system can be operated successfully without high efficiency inline air

filters. Product and process standards demand the finest quality air and

end products are now manufactured to such tight tolerance that no contamination

is permitted.

Compressed air is the most widely used

source of basic power in industry, which features such characteristics

including convenience, rapidness, safe and cost saving. However, pollutants

like water, oi fume, particles and odour exist in the system and they

combine into acid oil mud with causticity, which is the pollution source in the

compressed air.

These pollutants not only rust air pipes,

increase voltage (operation cost), damage precise instrument and cause machines

malfunction. In addition, they even influence the product quality, reduce

production efficiency, endanger body health and increase product cost. Dry and

clean compressed air is your best partner, it ensures the quality of your

products and reduces the possibility of production down time, so as to save you

a considerable amount of maintenance expenses and product costs.

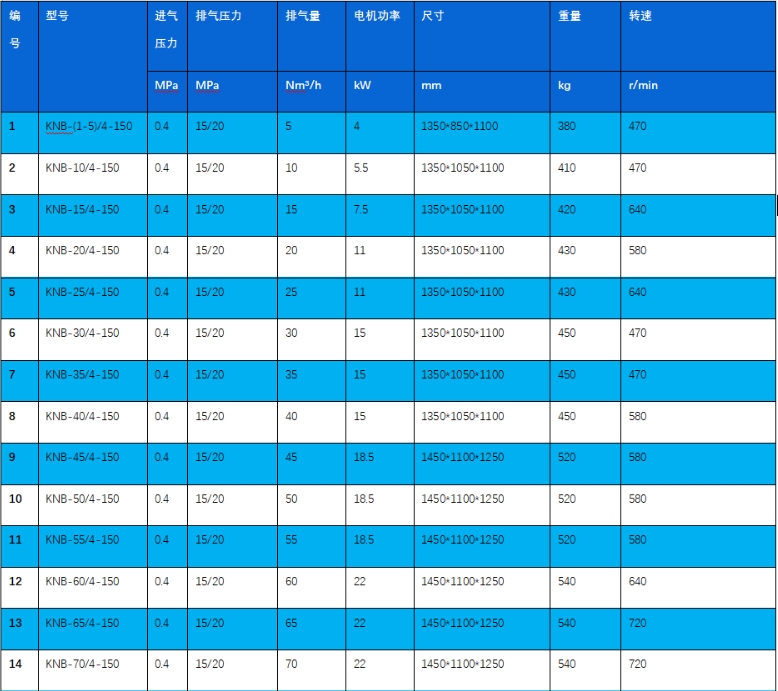

ADEKOM KAF series

inline filters are there to safeguard your system from unwanted pollutants,

whether it is compressed air for general factory or gas compression application

in remote dangerous zone, we have the right solution for your need!