Carbon Capture, Utilization, and Storage (CCUS) refers to technologies that capture carbon dioxide (CO₂) emissions from large point sources such as power plants, steel mills, cement factories, and biogas upgrading facilities and then either utilize or securely store the purified gas to mitigate climate change. CCUS is typically divided into four key stages: capture, transport, utilization, and storage.

1.Capture involves isolating CO₂ from industrial flue gases or biogas using chemical absorption, membrane separation, or adsorption methods.

2.Transport compresses and conveys the captured CO₂ often in liquid form via pipelines, tankers, or rail to utilization or storage sites.

3.Utilization repurposes CO₂ as a feedstock or additive across diverse industries:

4.Storage permanently sequesters CO₂ in geological formations such as depleted oil & gas fields or deep saline aquifers—or immobilizes it within building materials.

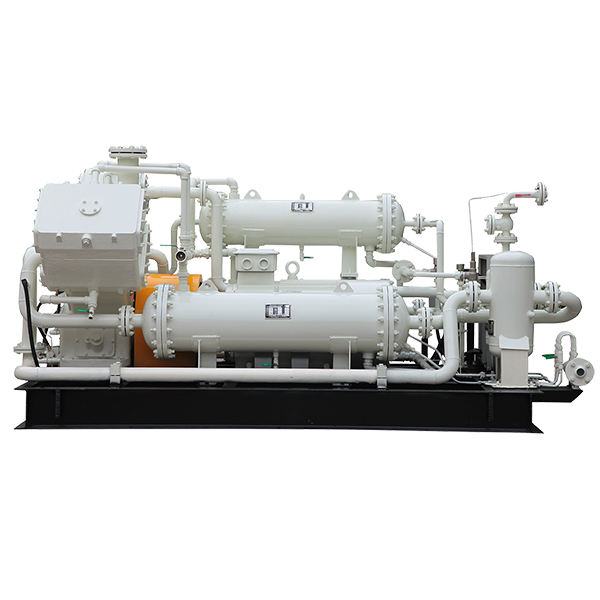

High-performance CO₂ compressors (or flue-gas compressors) are critical to CCUS systems. Their corrosion resistance, reliability, and energy efficiency directly influence overall capture rates and operating costs. Intelligent control systems optimize compressor operation, reducing power consumption and emissions and enable the CCUS chain to function with maximum effectiveness toward global greenhouse-gas reduction targets.

ADEKOM offers tailored gas-handling solutions for each CCUS phase, integrating CO₂ screw compressors, flue-gas compressors, and purification towers (absorption and wash columns) into turnkey modules:

1.CO₂ Screw Compressors

3.Purification Columns (Absorbers & Wash Towers)

Captura e Utilização de Carbono(CCU) / Captura y Utilización de Carbono(CCU) / احتجاز واستخدام الكربون(CCU)