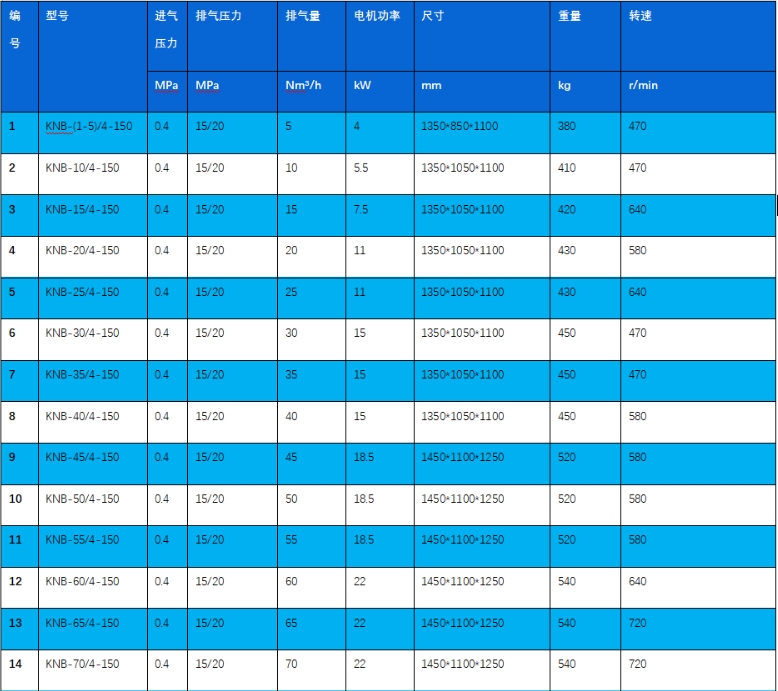

State-of-the-art Oil-free Biogas Screw Blower Gas-end

- Featuring a dry-type twin-screw oil-free gas-end, this unit ensures 100% oil-free compression—ideal for biogas and sensitive applications.

- Advanced aerospace-grade coating reduces rotor clearance, enhancing efficiency and durability.

- Proprietary rotor profile minimizes fluid dynamic losses, delivering up to 30% energy savings compared to traditional Roots blowers.

- Direct-drive configuration eliminates belt-related maintenance and improves system reliability.

- A precision-engineered gearbox optimizes rotor and motor speeds, enhancing stability and productivity.With a maximum pressure of up to 200kPa, it surpasses the 80kPa limit of conventional Roots blowers, enabling broader application coverage.