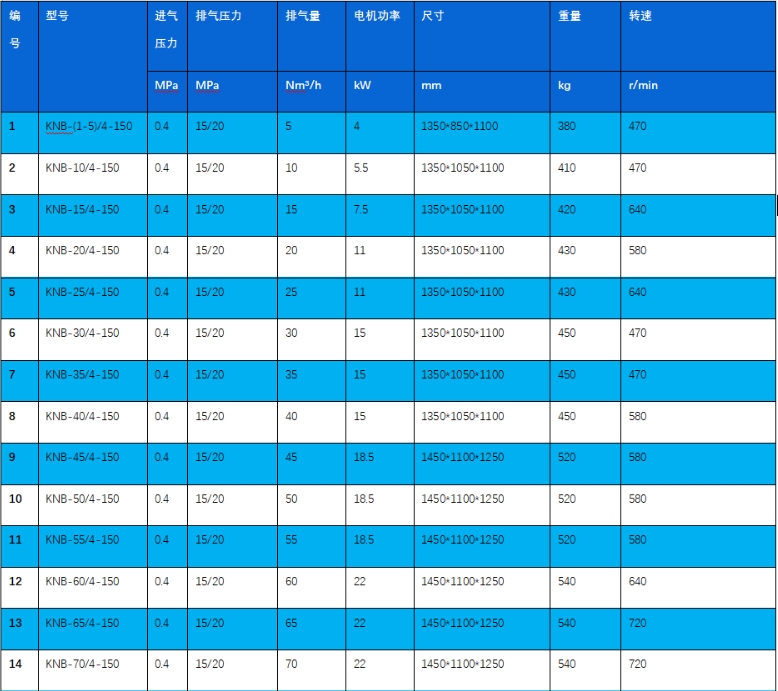

Designed especially to deliver 3-5bar with maximum energy efficiency, ADEKOM Low Pressure series is an innovative rotary screw compressor perfectly suited for low-pressure applications such as textiles, cement, glass blowing, water treatment, building materials and chemical industries.

Nowadays, most of the customers are operating 7-8bar compressors with pressure reducing valve at discharge when only 3-5bar system air pressure is needed, this causes huge energy wastage. By choosing Adekom’s Low Pressure series rotary screw air compressor, you can expect exact working pressure of air you need but produce much higher air capacity at the same motor rating which equivalent to saving of 20-50% electricity cost. This big saving can shorten the investment payback period to as quick as one year and it continues to pay you back with every hour of installation!