With extensive experience in the complex oil and gas sector, ADEKOM delivers reliable, safe compressor and downstream purification solutions tailored to your facility’s needs. From traditional olefins like ethylene and propylene to emerging applications such as fertilizer production, our standardized and fully customized systems support every segment - upstream gas wells and LNG, midstream processing, and downstream petrochemical operations.

In the midstream arena, our piston compressors are engineered for a wide range of critical tasks, including:

Partnering with ADEKOM means you’ll meet all your chemical and petrochemical compression requirements from a single source. Whether you need off-the-shelf packages, fully bespoke units, or integrated hybrid solutions, our comprehensive compressor lineup will perform in any application.

Typical process applications include:

1.Fertilizer (ammonia, urea, nitric acid)

2.Refinery (MTBE, FCC)

3.GTL (gas-to-liquids)

4.CTL (coal-to-liquids)

5.CTM (coal-to-methanol)

6.Aromatics from natural gas (PTA, phenol, caprolactam, maleic anhydride)

7.Syngas (hydrogen, carbon monoxide)

8.Olefins (ethylene, propylene)

9.Polyolefins (polyethylene, polypropylene)

10.Propane Dehydrogenation (PDH)

11.Carbon Capture

12.Enhanced Oil Recovery (EOR)

ADEKOM’s product portfolio for the oil & gas industry includes:

1. LPG Compressor Skid Packages

Compact, containerized modules requiring no additional auxiliaries, these energy-efficient units offer easy operation and low-maintenance design. Domestic performance matches or exceeds comparable imported models.

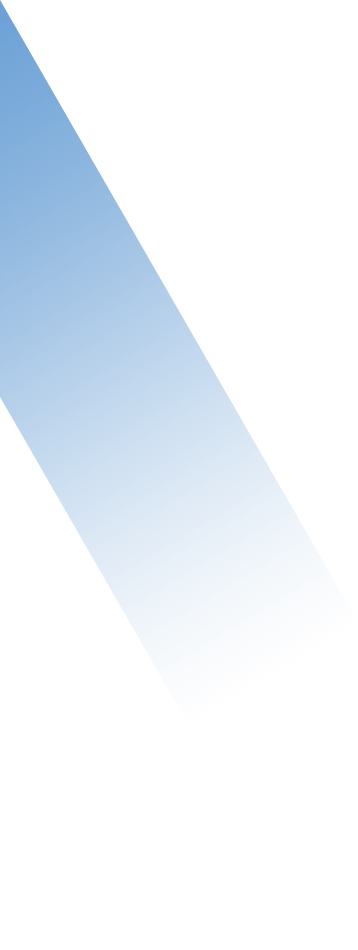

2. Explosion-Proof Process Gas Screw Compressors

Designed for flammable and explosive gases—including biogas, natural gas, associated petroleum gas, ethylene, propane, propylene, coke-oven gas, and coalbed methane—these integral‐skid compressors handle gas-lift, BOG recovery, CNG booster, and other high-risk applications with safety and reliability.

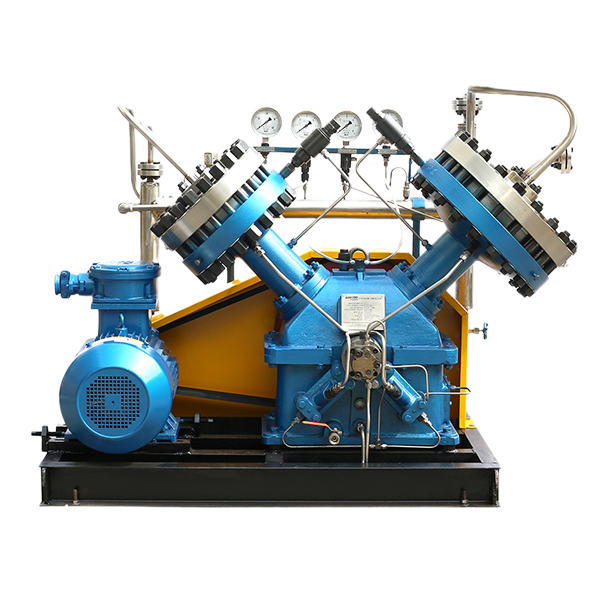

3. Multi-Stage CNG & Industrial Compressors

Available in D and M series, each skid integrates the compressor pump head, explosion-proof motor, cooling and lubrication systems, buffer vessels, valves, filters, oil separators, instrumentation, and PLC controls. Packaged on modular skids or in weatherproof containers, they’re ideal for CNG stations, truck-fill facilities, and industrial gas service.

4. Specialty Gas Screw Compressors

Our standard-duty screw compressors can compress a wide range of industrial gases—CO₂, vinyl chloride (C₂H₃Cl), NH₃, N₂, SO₂, He, and more—for applications in petrochemicals, upstream drilling, metallurgy, carbon capture, air separation, battery manufacture, and electronics.

5. Low-Boiling‐Point Two-Phase Transfer Compressors

Engineered for the safe handling, transfer, and storage of low-boiling‐point gas-liquid mixtures—such as ethane, ethylene, propane, propylene, butane, butylene, dimethyl ether, and difluoroethane—these units ensure precise metering and contamination-free operation under challenging temperature-cycling conditions.

Whether your project demands standard equipment or a fully bespoke solution, ADEKOM’s broad compressor range is engineered to meet the rigorous requirements of the global oil and gas industry.

Indústria de Petróleo e Gás / Industria del Petróleo y Gas / النفط والغاز